Renishaw, Equator™ gauging system (renishaw.es)

Metromecánica is a partner for the distribution and implementation of Renishaw systems and solutions.

We offer the complete solution at the level of implementation, programming of the control ranges, tooling, part handling systems and communication with the CNC machine.

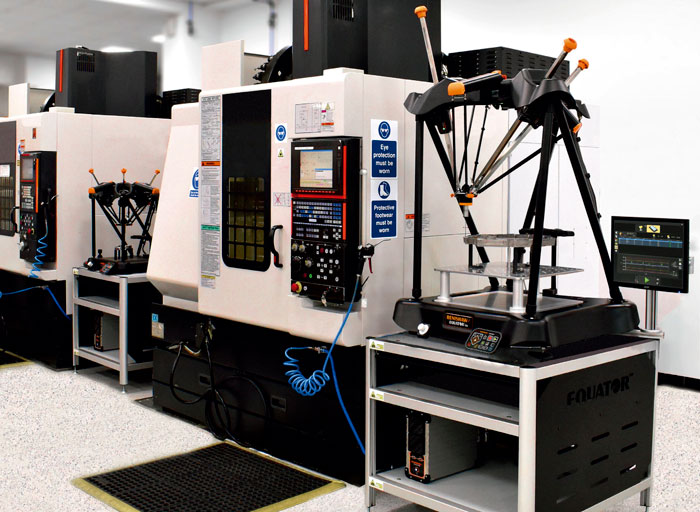

EQUATOR GAUGE SYSTEM

The Equator gauge allows control of the manufacturing process through a highly repeatable, thermally insensitive, highly versatile and reprogrammable comparison system for use in the workshop.

The Equator system is a flexible gage, designed to provide speed, repeatability and ease of use in manual or automated applications, which is why hundreds of manufacturers around the world are switching from their gauging systems and hand tools to Equator systems.

Some of the advantages of the Equator system:

- Reduce part rejection

- Reduce bottlenecks

- Low maintenance cost

- Easy automation

- Thermally insensitive

- Versatile and reprogrammable

Main characteristics of the Equator™ models

Equator™ 300

- Working volume XY: Ø 300 mm, Z: 150 mm

- Comparison uncertainty ±2 µm

- Operating temperature: From +5 ºC to +50ºC

- Maximum piece weight: 25 kg.

Equator™ 500

- Working volume XY: Ø 500 mm, Z: 250 mm

- Comparison uncertainty ±2 µm

- Operating temperature: From +5 ºC to +50ºC

- Maximum piece weight: 100 kg.