- Metrology Services

MEASUREMENT OF MACHINERY,

TOOLING AND INSTALLATIONSExperts in verification and commissioning

point of tools and mechanical assemblies.PRODUCT VERIFICATION

Dimensional inspection of parts

units and lotsREVERSE ENGINEERING

Digitized by scanning and

generation of 3D models.Major installations

Metrology management in large

automotive projects, aeronautics,

energy and Gics, large facilities

scientificAEC

We make reality captures in

architecture, engineering and construction.

We generate digital and BIM models.Equipment rental

We have the technologies

hardware and software you need - Automations

Inline automation

Te ayudamos a automatizar el control de tu

producción con un proyecto a tu medida.OFF-LINE AUTOMATION

We create inspection solutions

dimension of your production. - Product

ISI ROB

Robotic scanning station for non-contact measurement at the shop floor

SPATIAL ANALYZER

Advanced industrial metrology software for portable equipment

Faro

3D Measurement Solutions, Imaging & Realization

GAPGUN

Digital tool for manual or robotic use to control profiles.

Renishaw

Equator™ gauging system

ABB 3DMV (Metrology & Vision)

ABB Robotics | OmniVance™ 3D Quality Inspection - OmniVance™ Application cells

- Metromecánica

DIGITISED AEC - REALITY SNAPSHOT

We digitise large structures for architecture, engineering and construction projects AEC. We boost our clients’ digitisation by capturing the reality of their facilities and providing 3D models, digital twins, along with other virtual simulation and planning tools.

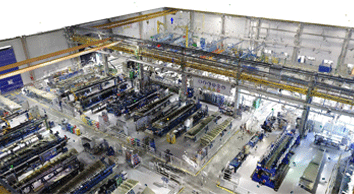

1. HIGH-VOLUME 3D SCANNING

Digitisation of facilities, buildings and infrastructures

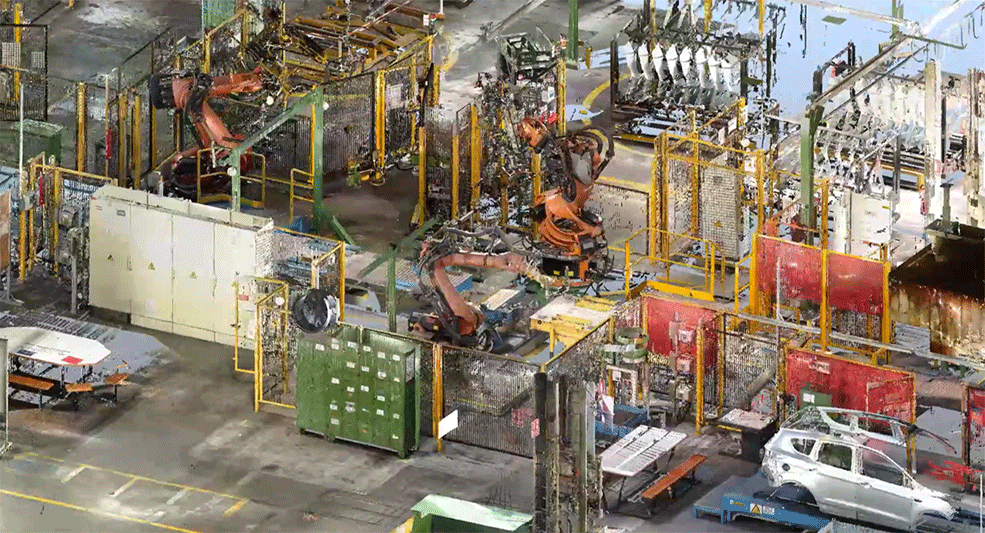

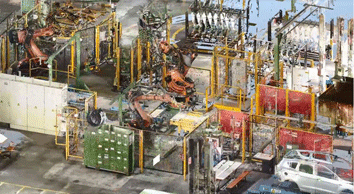

Automotive plant scanning

Free WebShare viewer: browser that allows you to virtually navigate your installation while employing 3D geometric and photographic information in colour. Extract measurements, areas, perimeters, label, attach and share documentation.

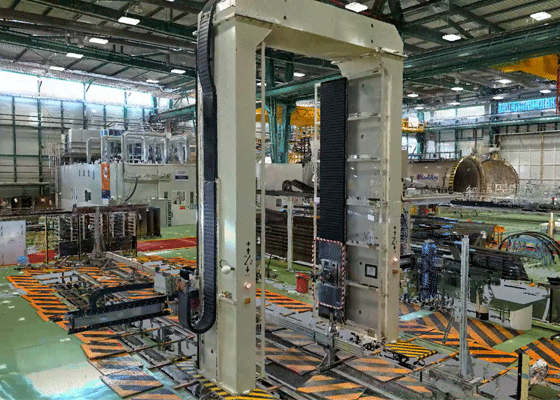

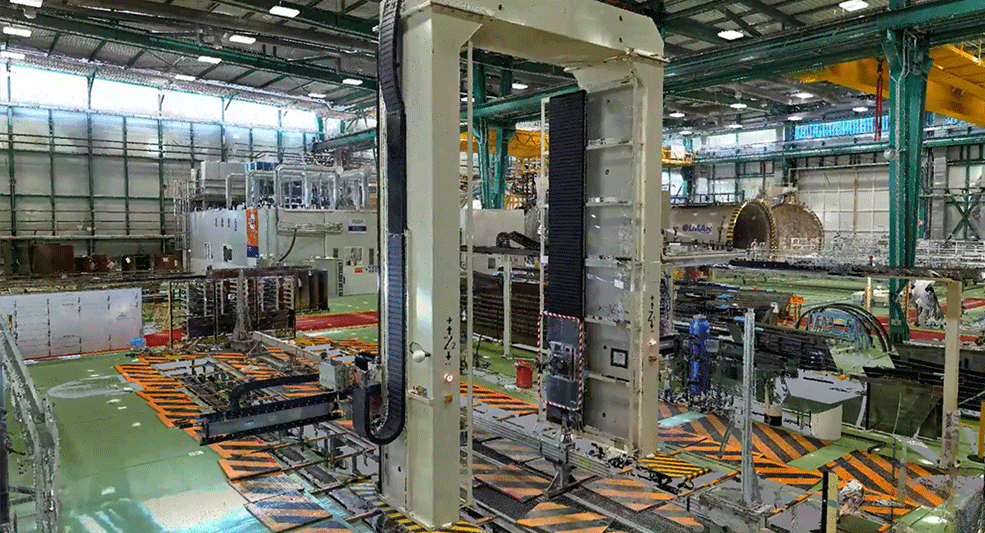

Aeronautical plant scanning

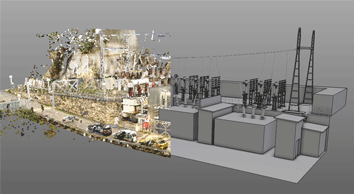

2. DIGITAL TWIN

GEOMETRIC REALITY SNAPSHOT

This consists of obtaining the digital model of a space from measurement technologies, photography and video 360°. The most widespread technique in industry is point cloud scanning combined with 360 images.

POINT CLOUD POST-PROCESSING

Process that aligns and joins the different scanning shots, generating a point cloud. These can be exportable to design software. They allow us to navigate, consult and take measurements.

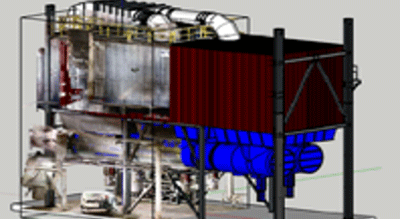

3D MODEL / DIGITAL TWIN

With the clouds it is possible to generate STL triangulated solid models, with a reverse engineering process surfaces and solid models are generated. This virtual model of the captured reality is the digital twin.

3. BIM MODEL

Speed and accuracy are the key factors for success.

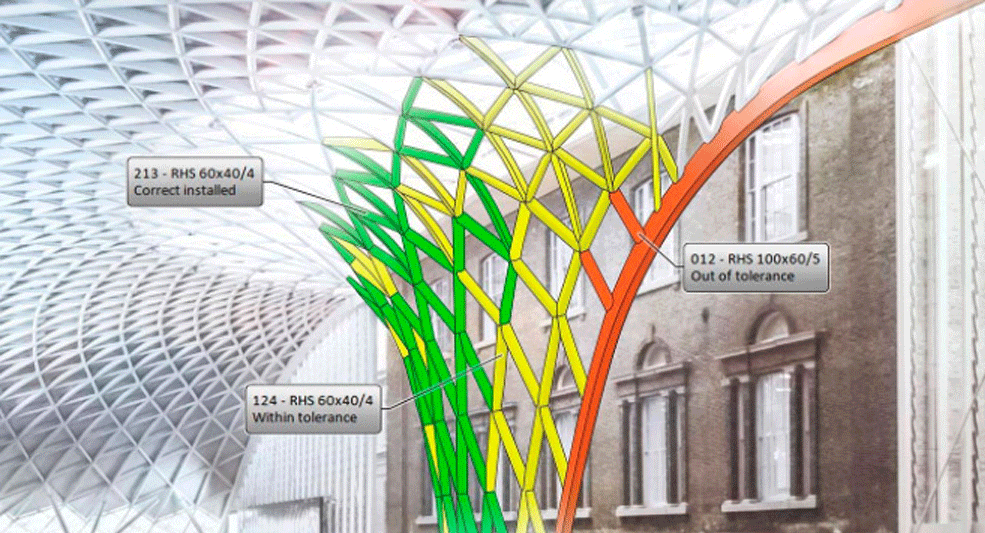

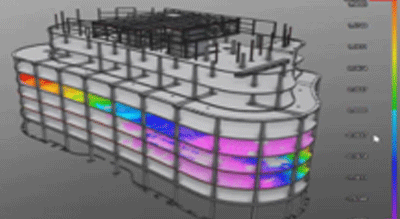

VERIFICATION OF BIM MODELS: the data obtained in the 3D scanning of new construction elements or modifications are compared with the design and deviations are obtained which, depending on the established tolerance, will determine whether it is acceptable and the next phase can commence.

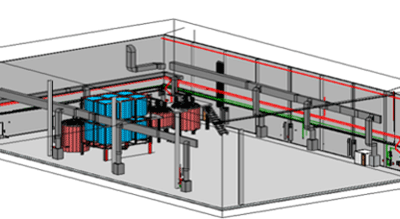

GENERATION OF BIM MODELS (building information modelling):

A partir de los datos obtenidos en el escaneo 3D de edificios existentes, se From the data obtained in the 3D scanning of existing buildings, the geometry of the constructive elements is modelled generating a virtual model of the geometric reality of the facility.

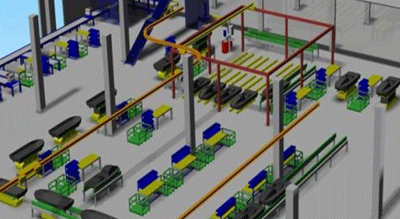

4. Smart Factories

The Smart Factory concept houses the digital twin of the facilities in a virtual platform fed with real data from the facility through sensors and other monitoring systems.

This provides relevant and accessible information in an updated virtual model, facilitating the control of industrial processes.

The data is analysed and conclusions are drawn. Using artificial intelligence, you can make decisions and act immediately to correct deviations.

Make decisions with confidence using accurate and detailed mock ups of yours detailed and production assets..

5. OTHER APPLICATIONS

Point clouds

In standard formats compatible with CAD software (e57, xyz, las) or specific formats: Autodesk (rcp, rcs), Bentley / Siemens: pod.

Digital twin

3D model equipped with non-geometric information to control your assets.

Virtual tours

Image and panoramic viewer. Supports VR/AR. Hyper-realistic photo quality renderings, fly thought flights.

Large volume geometric verification

Deformation analysis, deviation map, manufacturing error detection.

Reverse engineering

Solid models in step or iges format. BIM as built modelling: ifc, rvt.rfa format.

Layout markings

Scanning of complete production lines for retrofitting or relocations. Creation of dwg files and marking of points in new location.

Verification and work progress

Detect geometrical deviations in pillars, walls, floors, etc. Plus analyse the status and progress of the installation.

Simulation and analysis of collisions

Allows to integrate real data capture in the 3D design and detect possible interferences.

Infrastructures

Calculation and certification of volume and dimensions. 3D comparison for deformation analysis. Documentation of current status of spaces, virtual browsing and measurement.

OIL & GAS Maintenance

Fast, accurate and cost-effective method to monitor geometric stability in pipeline networks. 3D comparison between scans.

Heritage

Colour point clouds combined with high resolution digital images. 2D and 3D modelling, virtual tours with content of interest.

Inventory and planning

Identify your facility’s elements within the 3D model, visualize processes, workflows, stocks, layouts, etc.

Our engineers can work closely with customers at any stage of the project.